How ETL Identifies Manufacturing Defects in Children's Products

Uncovering Hidden Manufacturing Flaws

Forensic engineering plays an essential role in identifying manufacturing defects in children's products, ensuring that these items are safe for use and free of harmful substances. At MAS, we specialize in using forensic techniques to analyze these defects, providing manufacturers with critical insights to ensure their products comply with regulatory guidelines.

What Is Forensic Engineering?

Forensic engineering is the science of applying engineering principles in order to investigate defects or issues with systems, materials or products. This scientific discipline is particularly useful in cases where children's products have failed to meet safety standards due to manufacturing defects. Forensic engineers use advanced techniques such as ETL (Extract, Transform, Load) processes to examine and understand product failures.

For example, a toy or children's furniture might be found to contain harmful substances such as lead or asbestos, which are toxic if ingested or inhaled. These contaminants often enter products unintentionally, and forensic engineering helps to identify the specific stages in the manufacturing process where these errors occur.

How Forensic Engineering Identifies and Corrects Defects

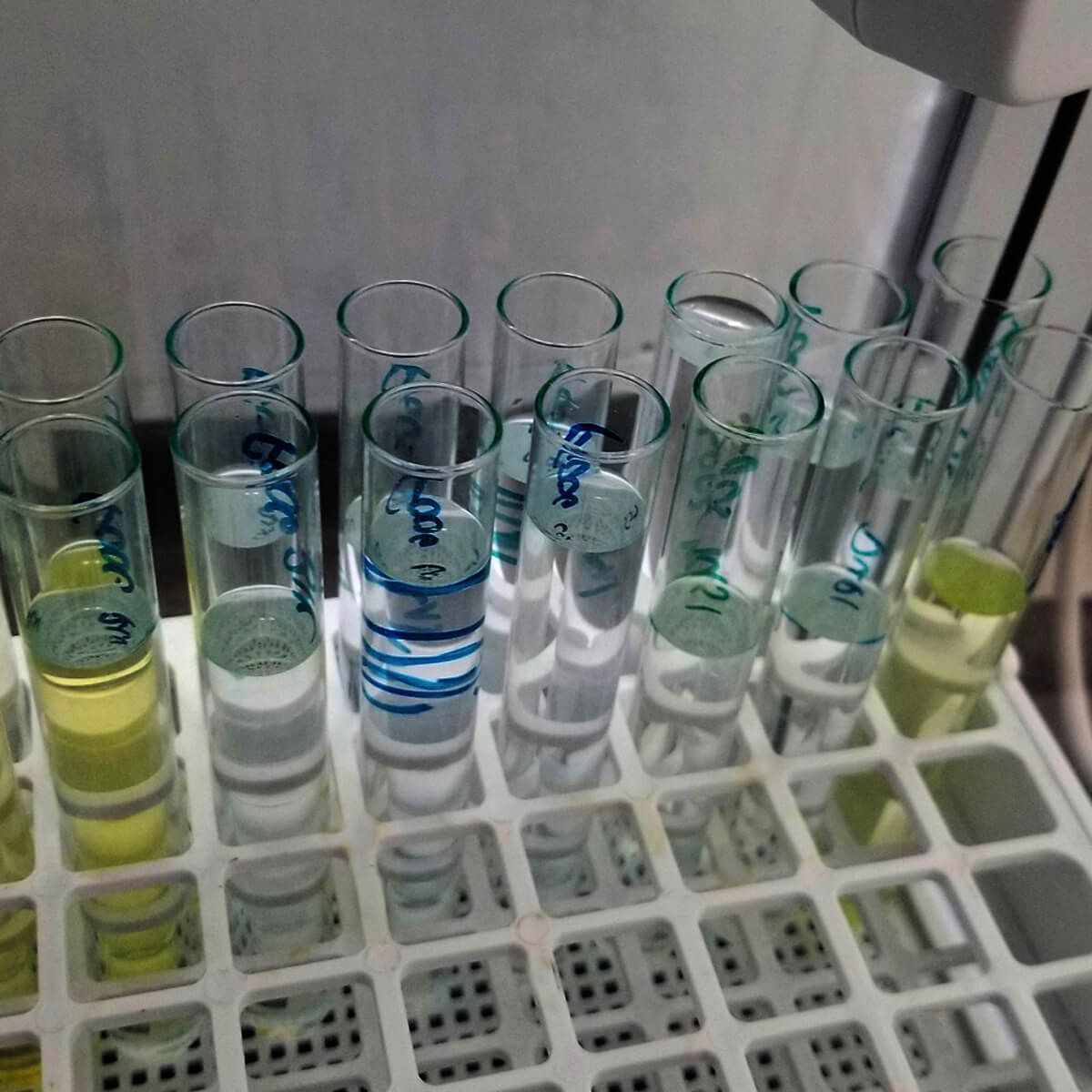

When a product designed for children poses a risk, forensic engineers begin by investigating the components and materials used in its construction. A product like a children's car seat might fail to protect a child during an accident due to material weaknesses or poor design, leading to potential liability claims. Using their expertise, forensic engineers at MAS can evaluate whether the manufacturing processes followed proper safety protocols and assess the presence of hazardous materials like lead or asbestos.

Incorporating ETL processes allows forensic engineers to extract data from the product's design and manufacturing history, transform it into meaningful insights, and load these findings into a comprehensive report for the manufacturer.

Ensuring Children’s Product Safety

The identification and correction of manufacturing defects in children's products are vital for maintaining safety standards. Forensic engineers do more than just identify the flaws—they also provide recommendations to manufacturers on how to improve their processes and prevent defects in the future. This is especially important for children's products, as even small defects can lead to severe consequences.

Forensic engineers at MAS are equipped to handle these complex investigations, using specialized tools like asbestos testing and lead testing to ensure products meet the strictest safety guidelines. They help manufacturers make informed decisions about product recalls, redesigns, or improved production methods, ultimately ensuring that only safe products reach the market.

How MAS Can Help

At MAS, our expertise in forensic engineering allows us to provide manufacturers with critical insights into their products. We help identify and correct manufacturing defects that could pose safety risks, especially in children's products. By using advanced testing methods like ETL, asbestos testing, and lead testing, we ensure that manufacturers meet stringent safety standards.

If you're a manufacturer looking to safeguard your products and ensure the safety of your customers, MAS can provide the expert support you need.

Sources:

- Analyzing the Role of Forensic Evidence in Georgia Product Liability Cases

https://www.keenanlawfirm.com/analyzing-the-role-of-forensic-evidence-in-georgia-product-liability-cases/ - Is Forensic Engineering Useful in a Product Liability Case?

https://fox-ae.com/is-forensic-engineering-useful-in-a-product-liability-case/ - Reasons You Need to Hire a Forensic Engineer

https://www.dreiym.com/2020/07/28/reasons-you-need-to-hire-a-forensic-engineer/ - Strategic Advantages of Involving a Forensic Expert in Product Liability Cases

https://www.envistaforensics.com/knowledge-center/insights/articles/strategic-advantages-of-involving-a-forensic-expert-in-product-liability-cases/ - What Is Forensic Engineering

https://www.regaeng.com/what-is-forensic-engineering

Resources

QUICK LINKS

CONTACT

© 2024 Materials Analytical Services, LLC. All rights reserved.