The Growing Concern Over Microplastics in Children's Products: How Forensic Engineering Can Help

Detecting Microplastic Contamination

Microplastics are becoming a growing concern, especially in children's products. Toys, clothing, and everyday items meant for kids are increasingly found to contain these tiny plastic particles, raising alarms about consumer health and the safety of these products. Microplastics are small plastic particles, usually less than 5mm in size, that can enter the environment and products through various means. At MAS, our forensic engineering services help manufacturers identify and eliminate this contamination.

What Are Microplastics and Why Are They Dangerous?

Microplastics are pervasive in the environment and have been detected in various consumer goods, including children's products. These particles can be ingested or inhaled, leading to potential health risks, particularly for children whose bodies are still developing. Microplastics can cause oxidative stress, DNA damage, and inflammation in biological systems.

Children are especially vulnerable to exposure because they often put toys and other items in their mouths. The risk of ingestion or inhalation of microplastics from such products can lead to long-term health issues. This growing awareness is pushing manufacturers to seek solutions to prevent microplastic contamination, and forensic engineering plays a crucial role in identifying the sources of these contaminants.

How Do Microplastics End Up in Children's Products?

Microplastics can enter children's products during the manufacturing process through raw materials, packaging, or even from the environment. These particles often originate from larger pieces of plastic that break down into smaller particles over time, a process accelerated by environmental factors.

This contamination is often invisible to the naked eye, making it difficult for manufacturers to detect without specialized expertise. Forensic engineering, coupled with ETL processes, allows experts at MASto thoroughly analyze products and their production methods. By extracting critical data from various manufacturing stages, transforming it into actionable insights, we help manufacturers improve their production lines and reduce the risk of microplastics.

The Role of Forensic Engineering in Ensuring Product Safety

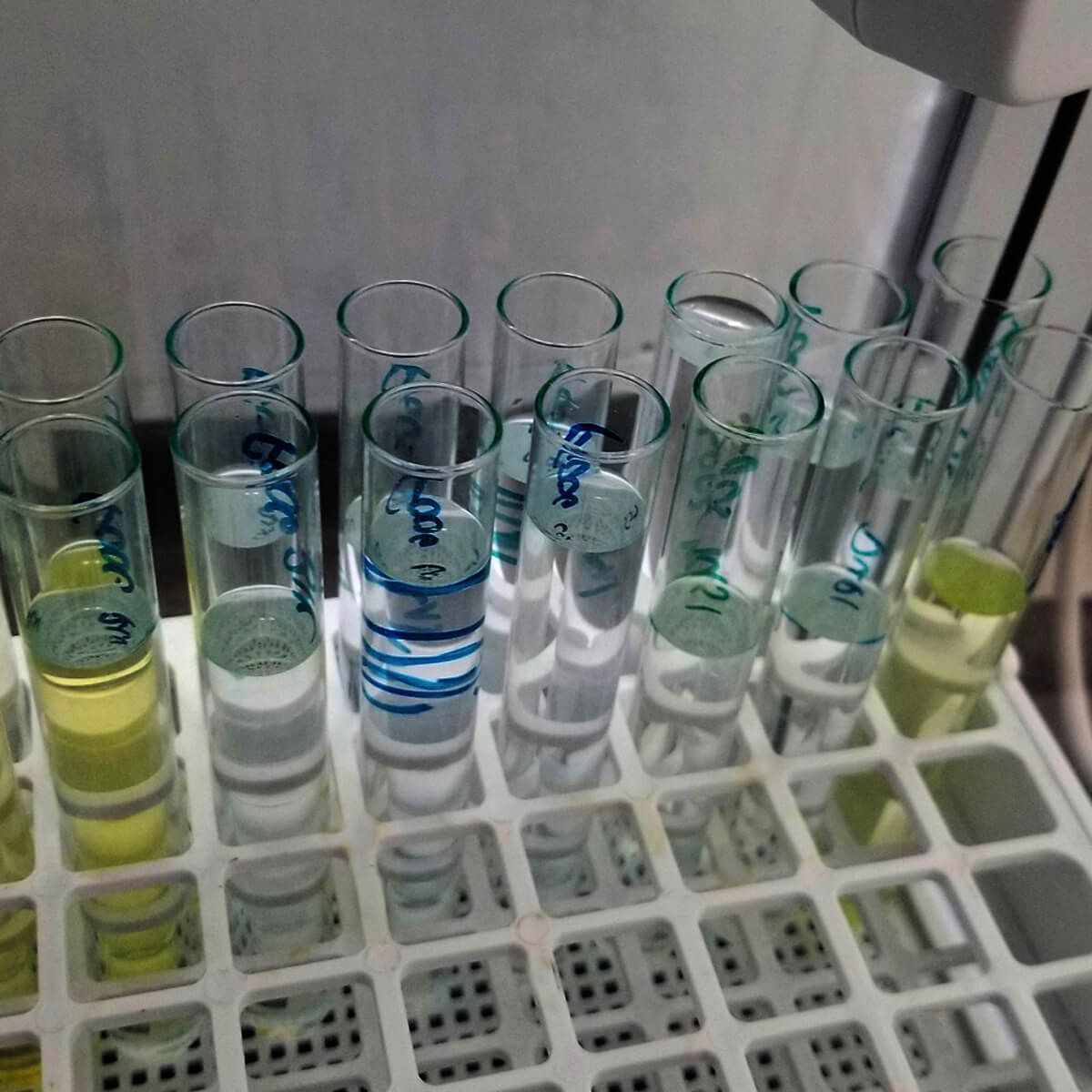

Forensic engineering is essential for identifying contamination risks and ensuring children's product safety. By applying advanced scientific methods, forensic engineers can detect even nanoscale microplastics that standard testing might miss. At MAS, our team uses cutting-edge technology to analyze materials and trace the origin of microplastics found in products.

Our forensic engineers evaluate the raw materials, production processes, and supply chains to find out where contamination occurs. This data allows manufacturers to make informed decisions about how to improve their operations and reduce future risks. The role of ETL in this process cannot be understated—it helps streamline materials analysis and reporting.

How MAS Is Leading the Fight Against Microplastic Contamination

MAS is at the forefront of helping manufacturers identify and address microplastics in children's products. We work closely with companies to ensure their products meet safety standards and comply with regulatory guidelines. Our forensic engineers provide more than just data—we offer solutions that help manufacturers improve their production processes and keep children safe.

If you're concerned about the presence of microplastics in your products or want to ensure they meet the highest safety standards, MAS can help.

Sources:

- Draft Science Assessment of Plastic Pollution

https://www.canada.ca/en/environment-climate-change/services/evaluating-existing-substances/draft-science-assessment-plastic-pollution.html - How Engineers Are Fighting Microplastic Pollution

https://www.ingenia.org.uk/articles/how-engineers-are-fighting-microplastic-pollution - Microplastics in Consumer Products: Exposure and Health Risks

https://pubmed.ncbi.nlm.nih.gov/25936572/ - Researchers Raise Alarm About Ingested Nanoscale Microplastic Particles Not Previously Evaluated

https://beyondpesticides.org/dailynewsblog/2024/01/researchers-raise-alarm-about-ingested-nanoscale-microplastic-particles-not-previously-evaluated/ - Understanding the Environmental Impact of Microplastics

https://pubs.acs.org/doi/10.1021/acs.est.0c07384 - What Does Crime Scene Investigations and Microplastic Research Have in Common?

https://oceandiagnostics.com/ocean-diagnostics-blog/post/what-does-crime-scene-investigations-and-microplastic-research-have-in-common

Resources

QUICK LINKS

CONTACT

© 2024 Materials Analytical Services, LLC. All rights reserved.