CASE STUDY | Welding Exposure Assessment: Is There a Health Concern with our Product?

Helping Clients Through Practical Analytical Solutions

Concern: Product Launch Delay

After years of development, a leading welding coatings manufacturer was ready to launch their newest product. But one thing was holding them up: unresolved concerns over workplace exposure during routine product use. The manufacturer didn’t have enough analytical data to allay concerns over worker safety, when plasma welding their new coating.

MAS Solution: Set up Real World Evaluation Environment

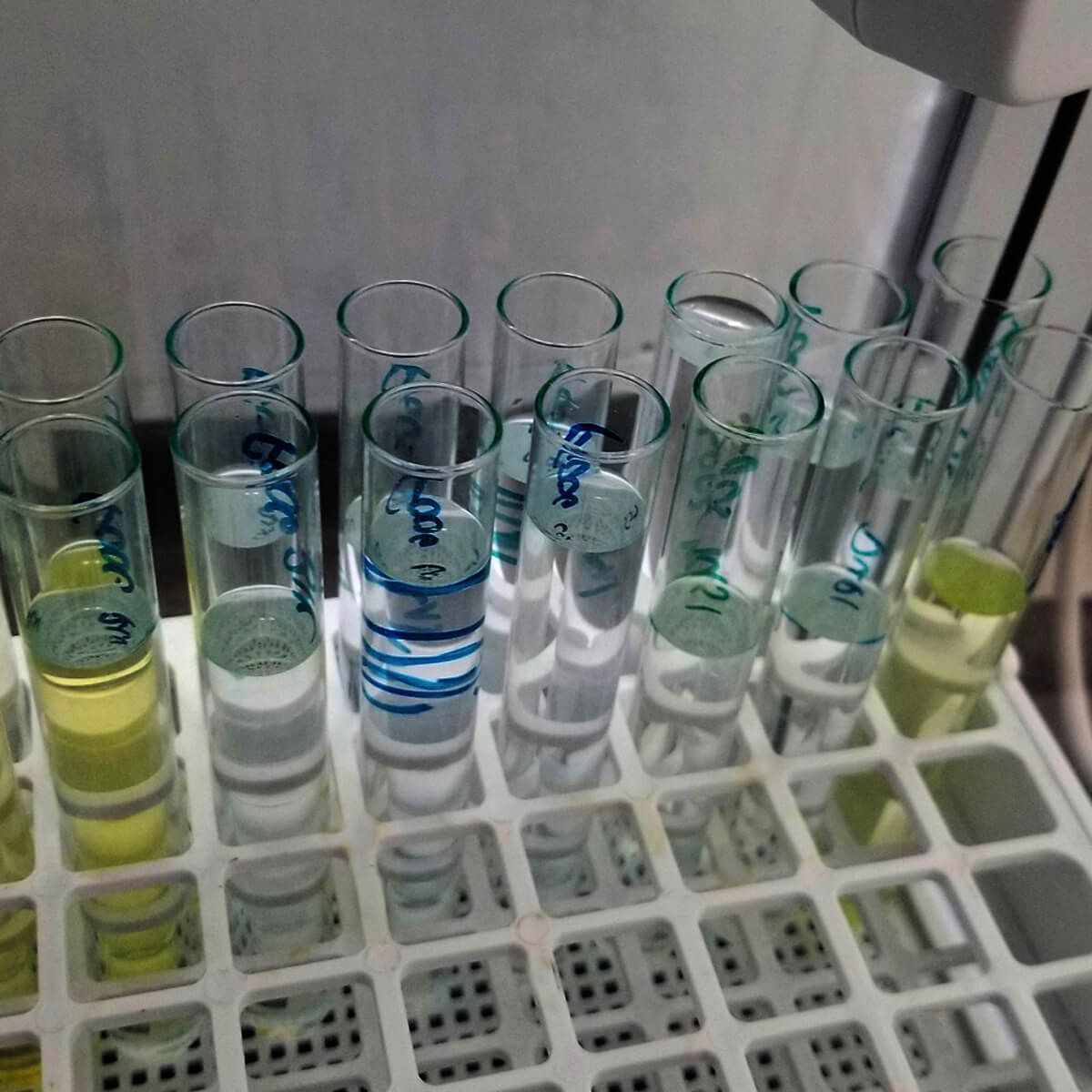

To help the client meet their launch date, MAS designed and conducted four evaluations in a compressed time schedule. To simulate real world conditions, MAS retained the services of a professional welder to cut and join pieces of steel covered with the new coating. To protect the welder, and effectively contain and measure any chemical fume/particulate releases, the evaluations were conducted in MAS’s environmental characterization lab (ECL). The ECL is equipped with an integrated decontamination unit and provides those inside with regulated breathing air. Containment of pollutants is achieved in the ECL through negative pressurization and HEPA air exhaust filtration.

Test Process: Data Collection

Forty area and 32 personal air samples were obtained over the course of the four evaluations. Airborne and surface particulates were analyzed using XRD, HPLC, GC/MS, GC/FID and ICP to determine not only sample composition, but also concentration levels.

Study findings were compared to applicable regulatory standards including OSHA PELs, NIOSH RELs, ACGIH TLVs and WHO limits.

The test design allowed MAS to determine which particulates were emanating from the steel, and which were from the coating during the welding process.

The tests yielded consistent data, which the client could use to accurately — and with a high degree of reliability — understand the chemical and particulate releases from their new coating product.

Results: Accurate Information for On-Time Product Launch

MAS’s reports to the client provided them with an assessment of both combustion and reaction products during plasma welding of coated steel plates. Based on the data in these reports, concentrations of dust and some of the target analytes were found in concentrations that approached and potentially exceeded applicable standards under certain conditions.

As a result of these findings, the manufacturer was able to report potential hazards in their product MSDS and provide recommendations relative to OSHA ventilation and respiratory protection requirements.

The manufacturer was able to successfully launch their new coating product on schedule, knowing they were in full compliance with corporate and industry due-diligence requirements.

MAS LABORATORY AND CONSULTING SERVICES

800-421-8451 • mastest.com

Resources

QUICK LINKS

CONTACT

© 2024 Materials Analytical Services, LLC. All rights reserved.